Among the most hazardous construction operations in the underground utility industry are trenching and excavation. Excavation is defined by OSHA as any man-made trench, cut, depression, or cavity formed by removal of the earth’s surface. A trench is a narrow underground excavation that is deeper than it is wide, and no wider than 15 feet.

Cave-ins, falls, and hazardous atmospheres contribute to dozens of injuries and even fatalities each year. Due to these dangers, OSHA requires that companies provide equipment designed to help keep their employees safe when working in trench excavations 4 feet or deeper. At EGW Gas Solutions, we supply a number of products that aid in protecting workers within these precarious environments, including trench shoring, telescoping ladders and intrinsically safe blowers/exhausters.

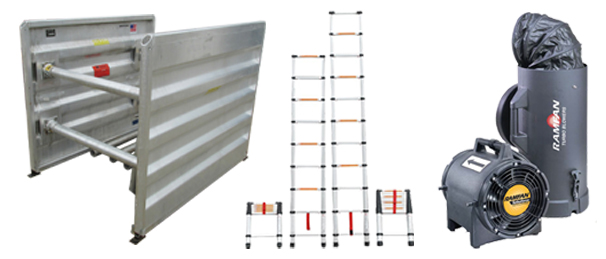

UltraSHORE Aluminum Trench Boxes

UltraSHORE aluminum trench boxes give workers protection in trenches up to 12 feet deep, even in Class “C” soils (gravel or sand). They are composed of a specially corrugated, puncture proof aluminum that weighs hundreds of pounds less than other shoring products.

All UltraSHORE panels can be used horizontally or stacked vertically, arranged as parallel shields or in a “vee” or “wedge” configuration, and each end can be closed off with quick-release, spring-loaded end closure panels. One panel pair can be assembled and lowered by a single person, and two people can lower a stacked assembly of two panels into an excavation. These panels are easily broken-down to fit in even the smallest pickup truck, or placed on one of our custom trailers for transport to and from the job site.

UltraSHORE Aluminum Trench Boxes are perfect for municipalities, utility companies, underground contractors and more!

Telesteps Telecopic Ladders

The safe, stable entry and exit of an excavation or trench is critical in limiting falls that can lead to injury or worse. To help with this, we offer 16 and 18 foot reach extension ladders from Telesteps.

These professional, wide-step, telescoping ladders are lightweight yet durable due to their Type 1A 300lb rated, aircraft grade aluminum construction. Wide step rungs allow for added safety and maximum grip and the 100% silicone pivoting feet help ensure it won’t slip. These ladders also feature a One-Touch release mechanism that allows for fully automatic up and down operation as well as safety indicator windows to tell you when it’s safe to climb.

Telesteps Telescopic Ladders are both OSHA Compliant and ANSI 14.2 tested.

Ramfan Intrinsically Safe Blowers/Exhausters

Exposure to hazardous gases is another risk that workers face when operating within trenches. Not only are the fumes dangerous to inhale, but the slightest spark can cause a devastating explosion. Proper gas exhaustion is essential before any construction or repair within the trench can be initiated. That’s where the Ramfan Intrinsically Safe Blower/Exhauster comes in.

The Ramfan UB20xx 8” explosion-proof blower/exhauster is manufactured to meet the requirements of the ATEX Directive, IEC standard and INMETRO standards. It can safely blow or exhaust hazardous gas with minimal risk of the fan causing a spark. It is built using only explosion-proof components along the electrical path and the whole unit is certified for safe use in combustible atmospheres. Anti-static ducts of various sizes are available to suit numerous settings.

This ultra-quiet, durable, compact and lightweight blower/exhauster will provide the user with the peace of mind that comes with knowing that they’re using a certified explosion-proof product!

Trench Safety is Always a Priority

No matter how complex the job, any time that utility work is to be done within a trench or excavation, proper equipment is needed to ensure worker safety. EGW Gas Solutions is able to provide the tools discussed as well as hundreds of other products designed to make underground utility operations more efficient and secure.

For more information about essential excavation safety equipment or other underground utility products, give us a call today at (972) 446-1655 or send us a message through our contact form.